Environmental monitoring is a top concern for pharmaceutical, food, and other industries that call for cold chain logistics to ensure consistency in conditions and compliance with industry regulations. For instance, temperatures that are even slightly out of range can cause insurmountable damage to product quality, wreck business partnerships, and pose a significant risk to consumers.

Complying with regulatory penalties and remediation efforts can be prohibitively expensive and may tarnish your company’s reputation. Putting in place the proper monitoring system can guarantee consumer safety, protect sensitive assets, and help your organization meet regulatory requirements.

Data loggers can play a crucial role in facilitating effective condition monitoring and thus considerably minimize risk associated with environmental factors. They can also serve as alarms, alerting key people when certain conditions, such as temperature, go out of a preset range.

In this post, we will take a closer look at the capabilities of data loggers and how they address common cold chain logistics problems in 2021.

Data Loggers Defined

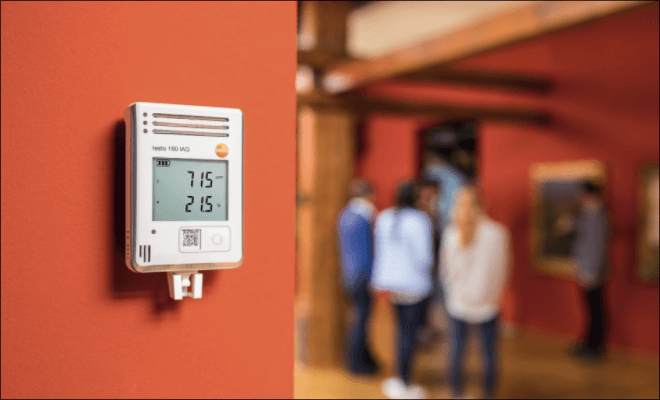

In cold chain logistics, data loggers are compact and versatile electronic environmental monitoring equipment. They are usually portable and function reliably without external hardware. Data loggers are fitted with sensors that consistently and regularly measure conditions like temperature, humidity, pressure, voltage, or CO2. This measurement information is fed into the microprocessor in the form of electrical signals.

The minicomputer takes the impulses and converts them into computable environmental data that can be sent to a storage unit or transferred directly to a data saving/retrieval system, such as a computer, server station, or cloud-based service.

Responsible personnel can read the information from the data logger’s user interface or a computer software tool. They can also download the environmental data onto an external hard drive or flash disk for further processing or archiving.

The main features of a data logger include sensory inputs, microprocessors, and data storage devices. Most of today’s data loggers are designed to allow real-time access and viewing of environmental data from anywhere and from any device, including tablets and mobile devices. This ability eliminates the need for manual uploading of data.

In cases where internet connectivity isn’t available, data loggers can download data directly via flash disks and other tools. They provide accurate condition monitoring across all points of the cold supply chain.

According to Dickson, data loggers are mainly used for temperature monitoring. But they can also measure and monitor a range of other parameters, including voltage, current, differential fluid pressure, relative humidity, CO2 levels, and air quality.

In general, data loggers are vital in settings, facilities, or processes that need detailed cold chain logistics. These include companies in highly regulated industries, such as food processing, packaging, food & beverage delivery, healthcare, and pharmaceuticals.

What Type of Data Loggers are Used in Cold Chain Logistics?

Data loggers designed for cold chain logistics are grouped into multiple categories:

– Wireless data loggers

Supply chain logistics data loggers are usually classified based on the method they use to communicate data. Wireless data loggers fall under the category of monitoring devices that wirelessly transmit environment data.

Subsets of wireless data loggers include:

- WIFI data loggers (connects via wireless internet)

- RFID (radio frequency identification) data loggers

- Bluetooth data loggers (also known as beacons)

Owing to their lack of hardwiring, these loggers are typically compact, easy-to-use for remote monitoring, and sport a slim profile. Of course, they’re cable-free, making them ideal for mobile condition monitoring.

– Mechanical data loggers

A mechanical data logger is a standalone device. It doesn’t need a computer, internet connectivity, or a network of supporting instruments to work. In this respect, they are the closest to paper chart recorders.

Other cold chain logistics data loggers on the market include QR loggers, universal input loggers, USB data loggers, and web-based data loggers.

How Data Loggers are Solving Common Logistical Issues

1. They Can Serve as Powerful Alarm Solutions

As noted above, a modern digital data logger can function as an effective alarm solution. It constantly monitors and records variations in conditions, quickly alerting organizations of any fluctuations that go out of the predetermined range.

These digital loggers can be configured to send precise notifications of unwanted deviations through email, phone calls, or SMS text. Relevant personnel can then receive instant alerts on mission-critical events such as sharp losses in pressure, power failure, or any breach in the cold chain.

In many respects, these data loggers transform the environmental monitoring of any cold chain logistics from reactive and proactive. Relaying timely alerts to the right people makes it easy and more proactive for the organization to take corrective measures before significant damage occurs.

2. Generate Actionable and Verifiable Data for Dispute Resolution and Compliance

Highly regulated industries like pharmaceuticals must adhere to a multitude of best practices, regulations, and guidelines. They must also provide a variety of environmental data collection and monitoring records upon request from agencies like the Drug Enforcement Agency (DEA), Federal Food and Drug Administration (FDA), Environmental Protection Agency (EPA), and the US Department of Agriculture (USDA).

Although most organizations try to exceed regulation standards in order to avoid product degradation and cold chain breaches, mishaps are inevitable. When that happens, the organization must be able to provide the evidential data needed to evaluate a reportable incident.

The information generated by data loggers like geo-location, condition data, and timestamps can be the difference between uninterrupted business operations and wallowing in lawsuits that can run into millions of dollars in settlements and fines. Data loggers can help amicably resolve disputes and find data-driven measures for preventing future mishaps.

3. Data Loggers Ensure Consistency in Conditions

Data loggers help protect the integrity of cold chain conditions by constantly collecting and monitoring environmental conditions (e.g., humidity, temperature, etc.) This is particularly important during shipment and delivery of sensitive products like vaccines and food. During transport products are subject to many environmental factors that can ruin their quality, safety, and potency.

The good news is that a data logger helps monitor essential conditions at every point of the cold chain process. Even better, they provide precise and verifiable documentation that manufacturers can easily access for clients, regulators, supply chain managers, and other stakeholders.[adsense]

4. Streamline Environmental Data Documentation and Reporting

The benefits of ensuring consistency in cold chain conditions can be tremendous, especially in documentation and compliance. By keeping ongoing and consistent data on primary environmental conditions, you can provide regulators with evidence of what you did to address any inconsistencies.

Data loggers help protect consumers as well as the company’s bottom line and its assets.