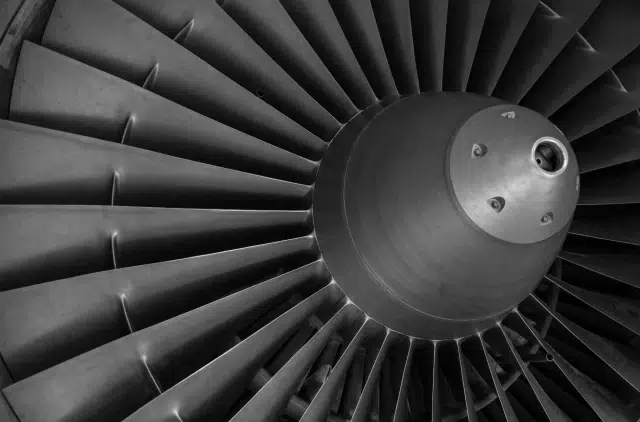

In aviation maintenance, precision is everything. Before technicians insert a borescope into a turbine engine, gearbox, or compressor section, they must be certain the device is functioning at its absolute best. According to remote visual inspection (RVI) best practices and aviation maintenance standards, pre-inspection calibration and testing are critical steps that directly influence inspection accuracy. Similarly, nondestructive testing research reinforces that even a small articulation issue or minor image distortion can cause technicians to miss early-stage defects that affect engine performance and safety.

A borescope may be sophisticated, but it is still a tool — and like all inspection tools, its performance depends on routine verification. Whether the device is used for hot-section evaluations, foreign object damage checks, or turbine blade assessments, proper calibration ensures that technicians obtain trustworthy data. This becomes especially important in business jet, helicopter, and private aircraft engines, where tight tolerances and complex geometries demand flawless visibility.

Why Calibration Matters in Aviation Borescope Inspections

Borescope calibration is not just a procedural step — it determines how accurately technicians can identify:

- Cracks

- Discoloration

- Blade tip wear

- Cooling passage blockage

- Thermal stress patterns

- Deposits and contamination

- Seal or gasket misalignment

- Foreign object debris (FOD)

Even the best inspection scope cannot compensate for uncalibrated optics or misaligned articulation. Aircraft engines rely on parts operating within extremely tight tolerances. If image quality is distorted or articulation is inconsistent, technicians may misinterpret findings or overlook developing issues.

Essential Pre-Inspection Checks for Borescope Accuracy

Before inserting a borescope into an engine, technicians perform a series of checks to confirm the device is ready for use. These checks improve clarity, ensure safe maneuvering inside the engine, and prevent equipment-related damage.

Below are the most important steps for proper pre-inspection calibration.

1. Check Image Quality and Sensor Function

High-resolution imaging is crucial for identifying subtle defects such as:

- Microcracks

- Surface oxidation

- Pitting

- Thermal discoloration

Before every inspection, technicians should verify:

- Sharpness: The camera should display crisp, clear edges.

- Brightness: LED intensity must be sufficient for dark engine chambers.

- Color accuracy: No abnormal tinting or white balance issues.

- Pixel integrity: No dead or flickering pixels on the screen.

Any degradation in image quality may lead to misdiagnosis.

2. Verify LED Light Output

Turbine and compressor interiors contain reflective and shadowed surfaces. Adequate lighting is essential for visualizing wear patterns.

Technicians confirm:

- Even lighting distribution

- No flicker in LED output

- Adjustable intensity response

- No overheating at the probe tip

Since aviation-grade borescopes rely on LED illumination to reveal heat damage or erosion, accurate light performance is essential.

3. Test Articulation Range and Smoothness

Articulation is what allows technicians to navigate around:

- Stator vanes

- Rotor blades

- Blade platforms

- Combustion liners

- Curved ducts

During calibration, technicians check:

- Full up/down/left/right movement

- Smoothness without lag

- No mechanical resistance

- Controller responsiveness

- Return-to-center consistency

Restricted articulation could damage engine components or prevent full inspection coverage.

4. Inspect the Probe and Sheathing

The insertion tube must be in excellent condition to prevent:

- Scratching internal components

- Depositing debris

- Getting stuck inside narrow passages

Technicians look for:

- Kinks

- Cracks

- Frayed sheathing

- Loose segments

- Contamination on the probe

Any defect may compromise inspection safety.

5. Confirm Measurement Tools (If Equipped)

Some videoscopes include measurement grids, stereo measurement features, or reference reticles. These tools must be accurate for evaluating:

- Blade tip clearance

- Crack depth

- Component spacing

- Wear progression

Calibration ensures measurement tools provide reliable, repeatable values.

6. Check Software and Recording Functions

Documentation is essential for trend analysis, warranty claims, and regulatory compliance. Technicians verify:

- Recording functionality

- Still image capture quality

- File saving and exporting

- Storage capacity

- Battery status

- Software responsiveness

Losing inspection footage can lead to repeat inspections — and costly downtime.

7. Perform a Final Cleanliness Check

Any contamination on the lens or probe can compromise visibility. A final wipe with approved, lint-free materials ensures a clean inspection tip before inserting it into the engine.

Why These Pre-Inspection Steps Are Critical

A properly calibrated borescope provides:

- Accurate visibility in reflective turbine environments

- Lower risk of misinterpretation from lighting or imaging errors

- Safer internal navigation through engine components

- Reliable documentation for OEMs and regulatory bodies

- Improved maintenance decisions when evaluating wear patterns

Skipping these steps increases risk — both to the engine and the accuracy of the inspection itself.

How USA Borescopes Supports Reliable Inspections

USA Borescopes provides aviation-grade remote visual inspection tools engineered for turbine and helicopter engine maintenance. Their products include 4mm articulating borescopes with 1.5-meter lengths, HD imaging, and video recording — ideal for high-pressure engine environments that require precise calibration.

In addition, they offer:

- No-cost repair evaluations

- Fast borescope rentals across the continental U.S.

- Overnight shipping where available

- Repair services for all makes and models

These services help aviation professionals maintain consistent inspection accuracy.

USA Borescopes – Remote Visual Inspection Specialist

Browse the wide selection of industrial videoscopes, pipe cameras, rigid borescopes, intrinsically safe systems, and fiberscopes available from USA Borescopes. Explore their full product catalog to find the perfect inspection tools for turbine and compressor evaluations. They also provide expert borescope repair services with no-cost evaluations. Need guidance before inspecting tricky or hard-to-see engine areas? Contact now for world-class support.