ABB contactors and automation control parts form the backbone of countless industrial operations worldwide, from manufacturing plants to power distribution systems. These components ensure reliable switching, motor control, and circuit protection in demanding environments where downtime translates directly to lost productivity and revenue. However, industrial technicians frequently encounter frustrating obstacles when sourcing these critical components — uncertain availability, long lead times, and the risk of counterfeit parts can disrupt maintenance schedules and compromise system integrity.

Understanding how to efficiently check ABB inventory and stock levels has become an essential skill for maintenance professionals. Real-time visibility into part availability allows technicians to plan preventive maintenance accurately, avoid emergency shutdowns, and maintain adequate spare parts inventory without over-purchasing. This guide addresses the practical challenges of locating, verifying, and procuring original ABB parts. Whether you’re replacing a failed contactor on an urgent basis or planning a scheduled maintenance cycle, the following sections will equip you with actionable strategies to navigate ABB’s supply chain, verify part authenticity, and make informed purchasing decisions that keep your automation systems running smoothly.

Understanding ABB Contactors and Their Applications

ABB contactors serve as electromechanical switches that control power flow to motors, lighting systems, heating equipment, and other high-current loads in industrial settings. These devices use a low-power control signal to safely manage much larger electrical currents, providing both operational control and protection against overloads. Within automation control systems, contactors act as the interface between programmable logic controllers and the physical equipment they manage, enabling remote operation and integration into sophisticated control sequences.

Manufacturing facilities rely heavily on ABB contactors for production line machinery, conveyor systems, and robotic assembly equipment. The mining sector depends on these components for material handling systems and ventilation controls in harsh underground environments. Water treatment plants use them to manage pump stations and chemical dosing systems, while commercial buildings incorporate them into HVAC systems and elevator controls. The marine industry trusts ABB contactors for ship propulsion systems and deck machinery, where reliability in corrosive saltwater conditions proves essential.

Original ABB parts deliver measurable advantages over generic alternatives through rigorous quality control, precise engineering tolerances, and comprehensive testing under extreme conditions. Genuine components maintain their switching performance across millions of operations, resist electrical degradation from arc formation, and provide predictable behavior under fault conditions. Generic substitutes often fail prematurely due to inferior contact materials, inadequate arc suppression, and inconsistent manufacturing standards. The initial cost savings disappear quickly when factoring in increased failure rates, unplanned downtime, potential damage to connected equipment, and the labor costs of repeated replacements. Original ABB parts also ensure compatibility with existing system designs and maintain warranty coverage for integrated equipment.

Checking ABB Inventory and Stock Levels

ABB provides multiple channels for checking real-time part availability, with the official ABB website serving as the primary resource. Navigate to the ABB product catalog section, enter your specific part number in the search field, and the system displays current stock status alongside technical specifications. The website indicates whether parts are immediately available, on backorder, or require manufacturing lead time. For contactors and automation components, the platform typically shows regional availability, allowing you to identify which distribution centers hold inventory closest to your location.

Authorized ABB distributors maintain their own inventory management systems that often provide more granular local stock information. Major industrial suppliers like Rexel, Graybar, and WESCO integrate ABB inventory data into their online platforms, displaying real-time quantities at specific branch locations. These distributor portals frequently update throughout the business day, reflecting recent orders and incoming shipments. Establishing accounts with multiple authorized distributors gives you comparative visibility across different supply chains, particularly valuable when sourcing hard-to-find legacy components or managing urgent replacement needs.

Lead times vary significantly based on part complexity and production schedules. Standard contactors in common voltage ratings typically ship within one to three business days when in stock. Specialized models with unique coil voltages or auxiliary contact configurations may require two to four weeks for factory fulfillment. Discontinued parts transitioning to successor models often experience extended delays of six to twelve weeks as remaining inventory depletes. When checking stock levels, note the difference between “in stock” status indicating physical warehouse inventory versus “available” status that may include parts currently in production or transit. For critical maintenance planning, always contact the distributor directly to confirm physical inventory location and reserve parts for your specific project, preventing stock-outs between your inquiry and actual purchase order placement.

Selecting the Right ABB Parts for Your Needs

Choosing the correct ABB contactor begins with identifying three fundamental electrical parameters: operating voltage, current rating, and load type. The coil voltage must match your control circuit specifications — common options include 24V DC, 110V AC, and 230V AC. The current rating should exceed your load requirements by approximately twenty percent to provide thermal headroom and extend contact life. Motor loads require contactors rated for the locked rotor current during startup, which can reach six to eight times the running current. Resistive loads like heaters demand less derating, while capacitive loads such as power factor correction banks need contactors designed to handle inrush currents without contact welding.

ABB part numbers follow a systematic structure that encodes critical specifications. A typical contactor part number like AF26-30-00-13 breaks down into identifiable segments: the AF series designation, frame size 26 indicating current capacity, pole configuration 30 for three-pole normally open contacts, auxiliary contact arrangement 00, and coil voltage code 13 representing 100-127V AC operation. Cross-reference your existing failed component’s part number against ABB’s catalog to identify direct replacements or approved equivalents. When specifications have changed in your application, use ABB’s online selection tools or contact technical support with your load characteristics, duty cycle, and ambient temperature conditions to receive verified recommendations.

The most frequent selection errors involve mismatching coil voltages with available control power, underestimating current requirements for motor applications, and overlooking environmental factors. Installing a 230V coil contactor on a 110V control circuit results in insufficient magnetic force and unreliable operation. Selecting contactors based solely on motor nameplate current without accounting for starting conditions leads to premature contact erosion. Ignoring temperature ratings causes thermal failures in enclosed panels or outdoor installations. Always verify that auxiliary contact blocks match your interlock and signaling requirements before ordering, as retrofitting additional contacts later may require different mounting hardware or prove physically impossible with space constraints in existing panels.

Where to Source Original ABB Parts

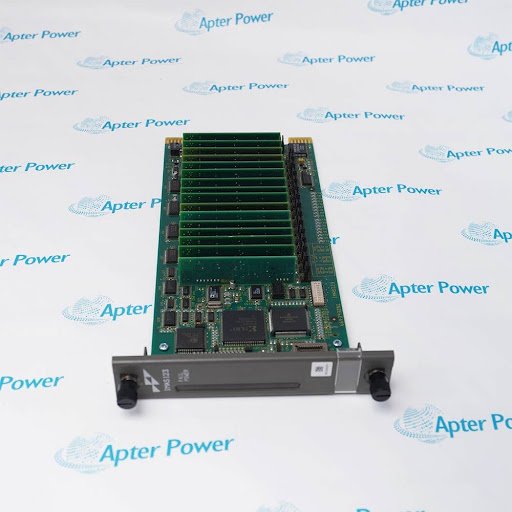

Authorized ABB distributors provide the most reliable channel for sourcing genuine components with full manufacturer support. Major industrial electrical suppliers including Rexel, Graybar, WESCO, and Crescent Electric maintain extensive ABB inventories across regional warehouse networks. These distributors receive products directly from ABB manufacturing facilities with documented chain of custody, ensuring authenticity and proper storage conditions. Specialized automation suppliers like Kendall Electric and Platt Electric focus specifically on control components and often stock deeper inventories of contactors, relays, and auxiliary devices. Additionally, specialized industrial spare parts providers such as Apter Power have emerged to serve facilities requiring comprehensive automation component sourcing alongside technical support for complex applications. Regional distributors frequently offer advantages for local projects through same-day pickup options, established credit terms, and technical support staff familiar with area-specific applications.

Verifying part authenticity requires examining several physical and documentation indicators. Genuine ABB contactors feature crisp, clearly molded logos without spelling variations or blurred characters. The product label includes a serialized QR code that links to ABB’s verification database when scanned with a smartphone. Packaging materials display consistent quality printing with proper grammar and technical specifications matching ABB’s published datasheets. Request certificates of conformity from your supplier documenting the distribution chain from ABB to your purchase. Counterfeit parts often reveal themselves through inconsistent screw head types, poorly finished plastic surfaces, lightweight construction suggesting inferior internal components, and documentation with grammatical errors or outdated formatting. When purchasing high-value components or large quantities, consider engaging ABB’s authentication service to verify serial numbers before installation.

Securing competitive pricing while maintaining delivery reliability involves strategic relationship building and timing awareness. Establish accounts with multiple authorized distributors to compare pricing structures, as margins vary between suppliers based on their volume agreements with ABB. Request project quotes for quantities exceeding five units, as distributors typically offer volume discounts beyond published catalog pricing. Time non-urgent purchases to avoid premium freight charges — standard ground shipping reduces costs significantly compared to expedited services. Monitor for manufacturer promotions during quarterly sales periods when distributors receive incentive pricing on specific product families. Building consistent purchasing relationships with a primary distributor often unlocks preferred customer pricing and priority allocation during supply constraints, proving more valuable long-term than constantly switching suppliers for marginal savings.

Ensuring Reliable ABB Parts Procurement

Original ABB parts deliver the reliability and performance that industrial automation systems demand, protecting your investment through superior engineering, rigorous quality standards, and predictable operational characteristics. While generic alternatives may appear cost-effective initially, the hidden expenses of premature failures, system downtime, and potential equipment damage make authentic components the only sensible choice for critical applications. The difference between a smoothly running operation and costly emergency repairs often comes down to the quality of components installed during maintenance cycles.

Successfully managing ABB part procurement requires understanding how to check real-time inventory across multiple channels, accurately identifying specifications that match your application requirements, and establishing relationships with authorized distributors who provide verified authentic components. Apply the stock checking methods outlined here to gain visibility into availability before maintenance windows arrive. Use the selection criteria to avoid common specification errors that lead to improper operation or shortened component life. Verify authenticity through physical inspection and documentation review to eliminate counterfeit risks from your supply chain.

Keep this guide accessible as your reference tool when planning maintenance activities, responding to unexpected failures, or upgrading automation systems. The strategies presented here will streamline your parts sourcing process, reduce procurement lead times, and ensure that every component installed meets ABB’s exacting standards. Proper parts management forms the foundation of efficient automation control systems — investing time in correct sourcing decisions today prevents the costly disruptions that compromise production schedules tomorrow.