The term might bring to mind old pocket watches or winding toys from another era. But clockwork springs – also known as power springs or spiral springs – are still very much in use today. And they’re doing more than driving gears in nostalgic mechanisms. They’re storing energy, releasing it in controlled bursts, and keeping precision systems moving across industries.

Whether it’s in a mechanical timer, a surgical device or a retraction mechanism in industrial equipment, the principle is the same: wind the spring, store the energy, release it with purpose.

Behind the simplicity lies a world of customisation, material science and mechanical precision.

Storing force – then letting go

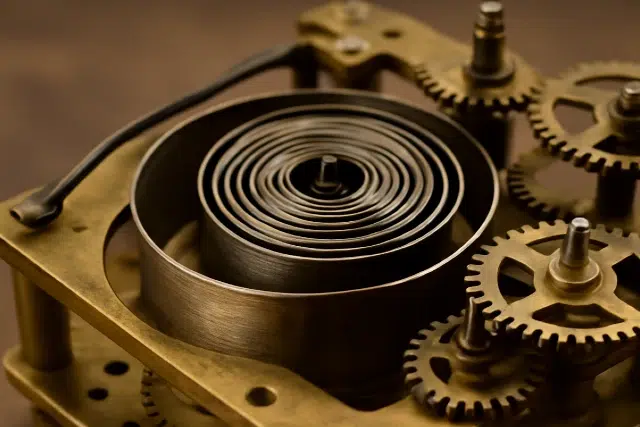

Clockwork springs are flat strips of metal wound into a tight spiral. When the strip is wound further – either manually or by a motor – it stores mechanical energy as tension. When released, that energy unwinds the strip in a controlled motion.

Depending on the design, the release can be rapid, delayed, or modulated over time. That makes them useful in systems where a battery or motor would be too bulky, expensive or unreliable – or simply unnecessary.

But getting the performance right requires more than winding a coil.

Spring width, thickness, material, winding direction, inner and outer diameters, and the number of turns all influence the torque profile and the release characteristics. And in most applications, standard doesn’t cut it.

That’s where companies like Hagens come in.

Building springs from function, not assumption

At Hagens, power springs aren’t mass-produced parts waiting on a shelf. They’re engineered from scratch to solve specific mechanical tasks. Sometimes that means designing a spring that delivers consistent torque over hundreds of revolutions. Other times, it’s about fitting into a tiny space without sacrificing energy output.

The company works with customers across sectors like medtech, agriculture, transport and automation – industries where compact motion control is essential, and where the spring itself plays a key role in the user experience or system performance.

A spring for a surgical tool may need to retract with the same force every time, under sterile conditions, with zero fatigue over thousands of cycles. Another, in a ruggedised setting, may need to function through temperature swings, dirt and vibration. What they share is the demand for reliability – and a tolerance for nothing less.

Materials and mechanics

Most clockwork springs are made from high-grade spring steel or stainless alloys. Material selection depends on environmental factors like moisture, chemical exposure, sterilisation, or long-term fatigue.

But the real performance comes from how the spring is processed. Edge quality, surface finish and winding precision determine whether the spring behaves the same on its hundredth cycle as it did on its first. Even minor variations in forming can create torque irregularities or premature wear.

That’s why Hagens works with tight tolerances and repeatable production processes – including tooling and fixtures developed in-house, specifically for each customer’s design. No shortcuts. No general-purpose setups.

Every spring comes with data, traceability, and the ability to repeat performance across production batches. In regulated industries, that’s not just a benefit. It’s the baseline.

Powered by people, not catalogues

Many of the systems that use clockwork springs are low-voltage, low-space, or off-grid. The spring isn’t a fallback. It’s the primary drive.

But designing the right spring requires more than an engineer choosing a shape. It requires collaboration. Hagens often enters the process early, when the mechanical function is clear – but the solution isn’t. From torque curves to installation methods, they help shape not just the spring, but how it works with the rest of the assembly.

And once it’s built, they can scale. Small runs from the Danish factory in Støvring. Large-volume series from the facility in China. Same quality systems. Same documentation. Same performance. Just more of it.

Winding forward

Clockwork isn’t outdated. It’s evolved. And in the right hands, it still delivers elegant, reliable motion without noise, heat or waste.

When built right, a power spring is quiet, compact and dependable. It doesn’t need power. Just design. And a place to let go.