In industrial environments, user interfaces are exposed to far more than human interaction. Cleaning chemicals, solvents, UV radiation, abrasion from repeated use, and mechanical wear often attack the surface of a product long before internal electronics show signs of failure.

This is why industrial graphic overlays must be engineered, not styled. When designed correctly, they protect functionality, preserve readability, and maintain brand integrity throughout years of harsh exposure.

Why Standard Overlays Fail in Industrial Conditions

Graphic overlays designed for consumer or light-duty applications rarely survive in industrial settings. The failure mechanisms are consistent and well-documented.

Common causes of premature overlay failure include:

- Chemical attack from cleaners, solvents, oils, and disinfectants

- UV degradation leading to fading, yellowing, or brittleness

- Abrasion from repeated actuation, gloves, or tools

- Delamination due to temperature cycling and moisture ingress

- Ink wear that compromises legibility and safety markings

Once an overlay degrades, the product often becomes unusable, even if the electronics remain fully operational.

Chemical Resistance Starts With Material Selection

Chemical resistance is not achieved through coatings alone. It begins with selecting materials that remain stable when exposed to real-world substances.

Industrial graphic overlays are commonly exposed to:

- Alcohol-based disinfectants

- Industrial cleaners and degreasers

- Hydraulic fluids and lubricants

- Acids, bases, or solvents, depending on the application

Effective design strategies include:

- Polyester films for superior chemical stability

- Subsurface printing to shield inks from direct exposure

- Hard-coated surfaces to resist solvent attack

- Chemically compatible adhesives that do not soften or migrate

Material choice plays a foundational role in long-term performance. For a deeper comparison of base film options, our analysis of polycarbonate vs polyester for graphic overlays explains how each material responds to chemical exposure, UV, and abrasion.

Chemical testing should reflect actual exposure patterns, not just short-duration wipe tests.

UV Exposure Is a Slow but Destructive Force

Ultraviolet radiation rarely causes immediate failure. Instead, it degrades overlays gradually and visibly.

Typical UV-related issues include:

- Color fading and loss of contrast

- Yellowing or haze in display windows

- Increased brittleness and cracking

- Reduced adhesive strength over time

Overlays designed for UV exposure rely on:

- UV-stable base films

- Lightfast inks rated for high-light environments

- Protective coatings that reduce UV penetration

- Color systems selected to age predictably

Even indoor industrial products can suffer UV damage when exposed to high-intensity lighting or sunlight through windows.

Abrasion Is About Use Cycles, Not Scratches

Abrasion resistance is often misunderstood as simple scratch resistance. In practice, it is about how an overlay performs under repeated use.

Primary abrasion sources include:

- Finger and glove actuation

- Repetitive key presses

- Cleaning with cloths or brushes

- Contact with tools or equipment

Design approaches that improve abrasion performance include:

- Subsurface printed graphics that cannot wear off

- Textured finishes that mask micro-abrasion

- Hard-coat layers matched to expected actuation cycles

- Controlled embossing to avoid stress concentration

A properly engineered overlay should remain legible and functional after hundreds of thousands or even millions of actuations. In highly automated production environments aligned with smart factory performance models, interface durability directly impacts uptime, maintenance cycles, and long-term operational efficiency.

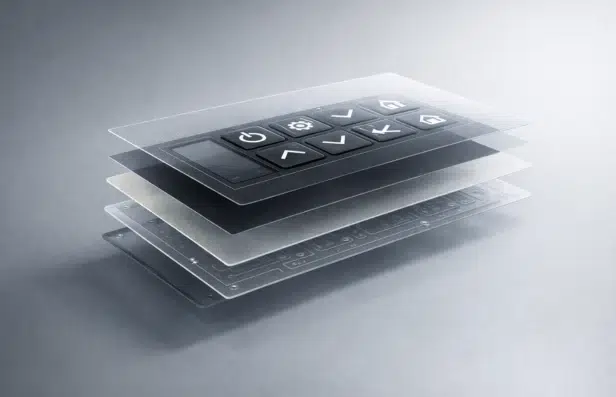

Layer Stack Engineering Determines Longevity

Industrial graphic overlays survive harsh environments not because of one feature, but because of how layers work together.

A high-durability overlay stack typically includes:

- A chemically resistant graphic overlay film

- Subsurface printed inks protected from exposure

- Hard coats or textures for abrasion resistance

- Adhesives selected for temperature and chemical stability

- Sealing strategies that protect edges and cutouts

Failures often occur at interfaces between layers rather than within the layers themselves.

Where High-Durability Overlays Are Essential

Overlays designed for chemicals, UV, and abrasion are critical in applications such as:

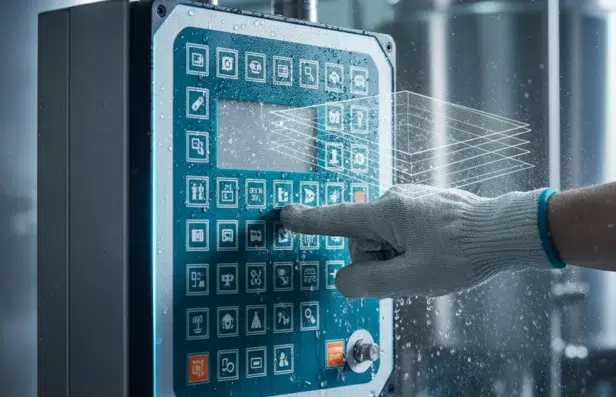

- Industrial control panels and HMIs

- Medical and laboratory equipment

- Food processing and washdown environments

- Outdoor and transportation systems

- Energy, utilities, and infrastructure equipment

In many of these systems, overlays are not just protective surfaces but structural elements within modular interface architectures.

This detailed article on how graphic overlays power modular industrial interfaces explains how overlay design influences scalability, maintenance, and long-term system flexibility.

In these settings, overlay degradation can create safety risks, compliance issues, or unplanned downtime.

Durability Also Protects Brand Perception

When an overlay fades, cracks, or wears through, the product appears neglected or poorly built, even if performance is unchanged.

Durable overlays help ensure:

- Controls remain readable and intuitive

- Safety labels stay visible and compliant

- Brand graphics remain consistent over time

- Products continue to look professional throughout their lifecycle

Manufacturers with experience in harsh-use interface design, such as Butler Technologies, often emphasize that overlay durability directly influences how users judge overall product quality.

Designing for Harsh Reality

Engineering overlays for chemicals, UV, and abrasion require accepting how products are actually used, cleaned, and maintained.

Design teams should focus on:

- Defining real chemical exposure, not assumed exposure

- Testing for long-term UV stability, not short-term appearance

- Designing for repeated use cycles, not single interactions

- Treating the overlay as a system, not a surface

Overlays that survive harsh environments do so because durability was engineered from the start, not added later.

FAQs

What makes an industrial graphic overlay chemical-resistant?

Chemical resistance depends on material selection, subsurface printing, compatible adhesives, and testing against real-world cleaning agents.

How do graphic overlays resist UV damage?

UV resistance is achieved through UV-stable films, lightfast inks, protective coatings, and color systems designed to age predictably.

Why do industrial graphic overlays wear out?

Overlays fail due to abrasion, chemical attack, UV exposure, or delamination when materials and layer interfaces are not matched to the environment.

Where are high-durability graphic overlays typically used?

They are commonly used in industrial controls, medical equipment, outdoor systems, food processing, and washdown environments.