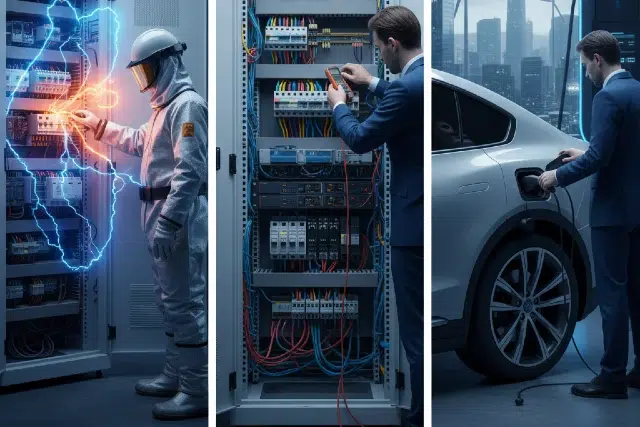

Electrical systems are the backbone of modern operations — but they’re also one of the fastest ways to rack up injuries, downtime, and compliance risk if they aren’t engineered, tested, and maintained with discipline. A good example of an integrated approach is Bowtie Engineering, a firm that combines electrical safety testing, incident energy studies, electrical maintenance, energy asset management, EV systems testing, and NFPA 70E training to help organizations run safer — and more reliably — at scale.

Why electrical safety and reliability are inseparable

People often treat “safety” and “reliability” as two separate initiatives — one owned by EHS and the other owned by engineering or facilities. In reality, they’re tightly linked:

- Safety failures (shock/arc flash incidents) often come from the same root causes as reliability failures (poor maintenance, undocumented changes, incorrect settings, aging assets).

- Compliance is not just paperwork; it’s a set of practices (risk assessments, labeling, training, and work controls) that reduce unplanned events and make planned work safer.

- Resilience depends on visibility: accurate one-lines, protective device coordination, maintenance records, and up-to-date studies.

When organizations align safety compliance with engineering rigor, they don’t just reduce incidents — they reduce outages, nuisance trips, and “mystery failures” that drain budgets.

The compliance baseline that keeps people alive

Most electrical safety programs rest on a few foundational pillars:

1) Risk assessment and incident energy analysis

Arc flash is one of the highest-consequence hazards in electrical work because it can cause severe burns and blast injuries in milliseconds. That’s why incident energy (arc flash) studies matter: they quantify hazards at equipment, inform labeling, and drive PPE/work planning decisions.

Bowtie Engineering explicitly offers incident energy studies (arc flash studies) designed to identify high-risk equipment, support accurate labeling, and align with NFPA 70E/IEEE methods.

2) Approach boundaries and controlled work zones

A key concept in NFPA 70E practice is establishing boundaries that trigger escalating controls (qualified personnel, PPE, and work methods) as you get closer to energized parts. OSHA also discusses how NFPA 70E uses boundaries to determine training and protective measures as proximity risk increases.

If your floor teams can’t quickly answer “Where is the boundary for this task?” the program is probably living in binders instead of behavior.

3) Training that stays current

Electrical safety training isn’t a one-and-done event. NFPA 70E retraining is commonly referenced on a three-year cycle, and many organizations add refreshers when conditions change (new equipment, new tasks, audit findings, or low-frequency high-risk work).

Bowtie Engineering offers NFPA 70E proctor-based training, emphasizing instructor-led oversight and practical demos to meet workplace expectations.

If you want a practical explainer on how often is arc flash training required, that training cadence is a good place to start — but remember: “minimum interval” shouldn’t be your only trigger for retraining.

Safety testing and maintenance: where programs succeed or fail

A study and a label are only as good as the real-world condition of the equipment they describe. This is where many facilities quietly drift into risk: settings change, equipment ages, and maintenance gets deferred until something breaks.

Electrical safety testing

Electrical safety testing helps validate that protective devices, grounding, insulation, and system performance are functioning as intended — before a fault turns into an incident or outage. Bowtie positions itself as an electrical safety testing company for critical facilities, focused on proactive assessment and safety compliance.

Electrical maintenance as a reliability strategy

Maintenance isn’t just about “keeping the lights on.” It’s about ensuring that clearing times and protective performance match the assumptions in your studies — so incident energy calculations, labels, and PPE requirements remain valid.

Bowtie also highlights electrical maintenance as part of its broader reliability and safety offering set.

Energy asset management: turning reliability into a system, not a scramble

Most organizations don’t fail because they lack smart people — they fail because they lack systemized visibility across a large, changing portfolio of electrical assets.

Energy asset management (done well) creates:

- A living inventory of switchgear, panels, UPS systems, generators, protective devices, and chargers

- Condition and maintenance history tied to each asset

- Standardized workflows for testing intervals, documentation updates, and corrective actions

- A defensible audit trail for compliance and insurance expectations

This is also where standardized engineering processes shine: consistency across sites reduces variance, which reduces surprises.

EV systems testing: safe and scalable charging is an engineering problem

EV charging adds a new kind of load growth: concentrated demand, site-specific constraints, and fast-changing hardware standards. Many “simple installs” become complex once you evaluate spare capacity, protective coordination, grounding, and demand management.

Bowtie explicitly calls out EV systems testing and the reality that many existing electrical systems “are not adequate for the new EV power demands,” requiring custom engineering per site — while still pushing standardization where possible to scale deployments.

A mature EV safety-and-reliability approach typically includes:

- Load studies and service capacity validation

- Protection and grounding verification

- Commissioning tests (including fail-safe behavior)

- Ongoing monitoring and maintenance planning (because chargers are assets, not appliances)

The arc flash boundary: more than a number on a label

Teams often treat boundaries as static distances, but in practice they’re a control mechanism — a way to enforce who can enter, what PPE is required, and what procedures must be followed.

For a plain-language overview of the arc flash boundary concept and how boundaries guide training/protection decisions as workers get closer to hazards, OSHA’s guidance document is a strong reference point.

What “good” looks like: an integrated operating model

An electrical safety and reliability program tends to work best when it behaves like a lifecycle:

- Assess: gather accurate system data; confirm field conditions

- Analyze: incident energy studies, coordination insights, risk controls

- Implement: labeling, procedures, boundary controls, training

- Maintain: testing, corrective actions, documentation updates

- Manage assets: standardize portfolios, plan refresh cycles, track risk

- Scale new loads safely: EV charging and other electrification initiatives

Bowtie Engineering is a useful example of this “integrated stack,” spanning electrical safety testing, incident energy studies, electrical maintenance, energy solutions/asset-oriented services, EV systems testing, and NFPA 70E training under one operational umbrella.

Bottom line

Electrical safety, compliance, and energy system reliability aren’t separate checklists — they’re one system. When you treat studies, training, testing, and maintenance as connected parts of an operating model, you reduce injuries, reduce downtime, and gain confidence that your infrastructure can support growth — especially as electrification (like EV charging) accelerates.