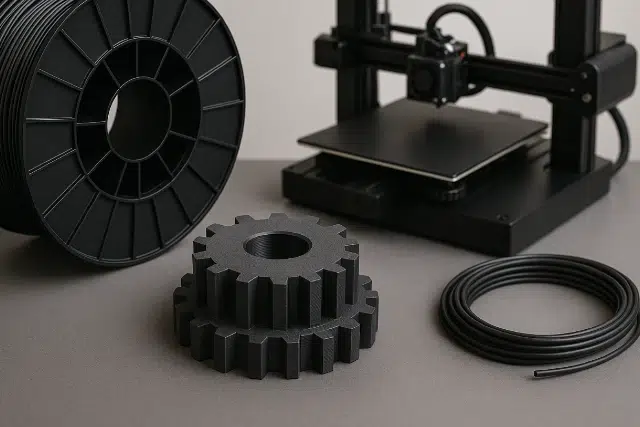

If you’re aiming to create reliable, functional, and long-lasting 3D printed parts, ABS filament stands out as one of the strongest options available. Known for its impressive durability and ability to resist high temperatures, ABS remains a top choice for hobbyists, engineers, and manufacturers who require prints that can perform in real-world conditions. Whether you’re developing mechanical components, automotive prototypes, or rugged enclosures, ABS filament provides the strength and heat resistance needed for demanding applications.

What Is ABS Filament?

ABS, or Acrylonitrile Butadiene Styrene, is a well-known thermoplastic used in countless consumer and industrial products. It is the same material found in LEGO bricks, automotive interior panels, electrical housings, and many consumer electronics. In 3D printing, its popularity comes from its impact resistance, rigidity, durability, and its ability to undergo post-processing such as sanding, painting, drilling, or acetone vapor smoothing. These characteristics make ABS a versatile material capable of producing both functional and aesthetic results.

Why ABS Filament Is Ideal for Durable and Heat-Resistant Prints

1. Superior Strength and Long-Term Durability

ABS filament is widely recognized for its toughness. Compared to PLA, it performs better under stress and maintains structural integrity even when exposed to vibrations, force, or impact. This resilience makes it suitable for parts that require mechanical strength, such as gears, brackets, handles, and machine components. Because of its slightly flexible nature, ABS can absorb shocks without cracking, offering a longer lifespan than more brittle alternatives.

2. Outstanding Heat Resistance

One of the key advantages of ABS filament is its ability to withstand high temperatures. While PLA begins to soften at around 60°C, ABS maintains stability up to approximately 100°C or more, depending on the formulation. This heat resistance is essential for prints exposed to warm environments, such as automotive interiors, electronic device housings, or components near motors. As an example, an ABS-printed dashboard mount can tolerate summer temperatures inside a vehicle — conditions that would typically deform PLA.

3. Excellent Post-Processing Flexibility

ABS is extremely easy to modify after printing. You can achieve a smooth, glossy, injection-molded appearance by applying acetone vapor smoothing. Sanding is straightforward because the plastic layers blend smoothly, allowing you to remove imperfections or prepare the surface for painting. The material accepts most adhesives and spray paints, making it ideal for cosplay props, product prototypes, and concept design models that require a refined finish.

4. Chemical Resistance for Tough Environments

ABS exhibits strong resistance to common chemicals such as alkalis, alcohols, and certain oils. This makes it suitable for applications in workshops, laboratories, and industrial environments where parts may regularly contact greases, cleaning agents, or mildly corrosive substances. Because of this resistance, ABS is often chosen for housings, containers, and mechanical components that must remain stable despite frequent exposure to chemicals.

5. Reliable Performance for Mechanical Components

ABS filament is especially valued for functional and mechanical 3D printing applications. Its strength and temperature tolerance allow it to perform well in gears, brackets, joints, clamps, and robotic components that must handle repeated motion or load. In one real-world case study, a PLA motor mount deformed after about 20 hours due to heat. The same part printed in ABS lasted more than 200 hours without warping, demonstrating how well ABS withstands demanding conditions.

How ABS Filament Compares to Other Materials

ABS vs. PLA

Compared to PLA, ABS offers significantly higher durability, better impact resistance, and superior heat performance. PLA prints easily and is great for decorative models, but its brittleness limits its use for mechanical or load-bearing applications. ABS, on the other hand, is designed for long-term functional use, making it suitable for engineering, automotive, and industrial printing needs.

ABS vs. PETG

PETG is popular for its ease of printing and balanced properties, but ABS surpasses it in high-temperature environments and applications that require rigidity. While PETG is more flexible and less prone to warping, ABS remains the better choice when temperature stability and post-processing capabilities matter most.

Challenges of Printing ABS (and How to Solve Them)

Printing ABS filament can be challenging, especially for beginners, but understanding its requirements makes the process easier. Warping is one of the most common issues because ABS contracts as it cools. Using a heated bed set between 90°C and 110°C, printing inside an enclosed chamber, and applying adhesives such as glue stick or ABS slurry can significantly reduce warping.

Another challenge involves the fumes emitted during printing. ABS should always be used in a well-ventilated space or an enclosed printer with proper filtration. Layer adhesion issues can also arise if the ambient temperature fluctuates. Maintaining consistent heat, avoiding drafts, and increasing the nozzle temperature to between 235°C and 260°C improves overall print quality.

Best Uses for ABS Filament

ABS filament is suitable for a wide range of applications because of its strength, durability, and heat resistance. In industrial and engineering contexts, it is frequently used for jigs, fixtures, housings, and functional prototypes. Automotive designers rely on it for dashboard elements, brackets, and components that must hold up in warm environments. The consumer electronics industry employs ABS for sturdy casings and protective parts. Hobbyists also appreciate it for drone frames, remote-control vehicle components, and cosplay armor that requires a smooth, paintable surface.

Tips for Achieving the Best Results With ABS Filament

To get the best performance from ABS, it helps to print inside a fully enclosed chamber to keep temperature stable. Allowing the part to cool slowly inside the enclosure prevents cracking and delamination. Modified versions such as ABS+ provide easier printing with reduced warping while retaining strength. Storing filament in airtight containers protects it from moisture, which can otherwise cause bubbling or poor layer adhesion.

Recommended ABS Printing Settings

Most ABS filaments perform well at nozzle temperatures between 235°C and 260°C and bed temperatures of 90°C to 110°C. A closed build environment significantly improves print quality, especially for large or tall models. Print speeds between 40 and 60 mm/s offer a good balance between quality and efficiency, and cooling fans should be kept off or at very low speeds to maintain layer adhesion.

Frequently Asked Questions (FAQs)

Is ABS filament stronger than PLA?

Yes. ABS is more durable and impact-resistant than PLA, making it better for mechanical and functional parts.

Can ABS be used outdoors?

ABS performs moderately well outdoors, but long exposure to UV light can cause fading or brittleness unless the part is painted or UV-treated.

Is ABS safe to print indoors?

ABS emits fumes and should be printed in a ventilated space or inside an enclosure with proper filtration.

How heat-resistant is ABS?

Most ABS filaments maintain their shape up to around 100°C, giving them excellent stability in warm environments.

Conclusion

ABS filament remains one of the most reliable and versatile materials for creating strong, durable, and heat-resistant 3D prints. Its toughness, thermal stability, and exceptional post-processing options make it a top choice for engineers, designers, and hobbyists who need functional parts that last. With the right printing environment and settings, ABS delivers professional-quality results that go far beyond what basic materials can achieve.